We're sorry. An error has occurred

Please cancel or retry.

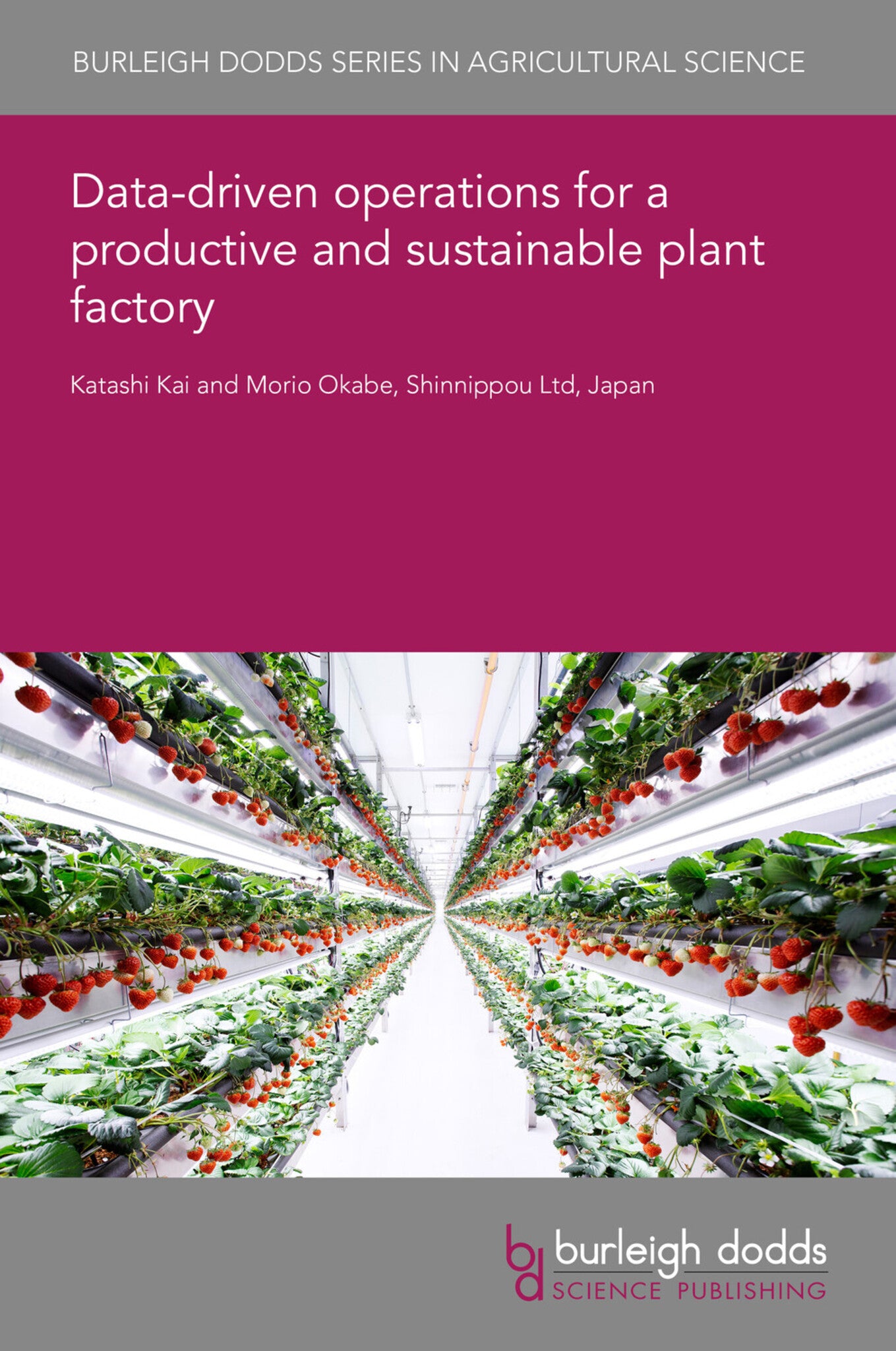

Data-driven operations for a productive and sustainable plant factory

Some error occured while loading the Quick View. Please close the Quick View and try reloading the page.

Couldn't load pickup availability

- Format:

-

14 September 2023

Our “808 FACTORY” business has been profitable for eight years since establishment of our first plant factory. Here, we present the business model of the brand that we have been operating. We discuss factory layout and operation management. We review measures of productivity per unit cultivation area, per unit of electric energy consumption, per labor hour and merchantability/commercialization ratio. We also outline control of variables such as temperature, photoperiod, airflow, CO2 and nutrient supply.

SCIENCE / Life Sciences / Horticulture, Commercial horticulture, TECHNOLOGY & ENGINEERING / Agriculture / Agronomy / Crop Science, TECHNOLOGY & ENGINEERING / Agriculture / Sustainable Agriculture, Sustainable agriculture, Agricultural science, Agronomy and crop production

- 1 Introduction

- 2 Business model

- 3 Factory layout

- 4 Cultivation room and operations management

- 5 Measuring productivity

- 6 Controlling cultivation variables

- 7 Other technologies and future trends

- 8 References